Pressure Testing

What is Pressure Testing?

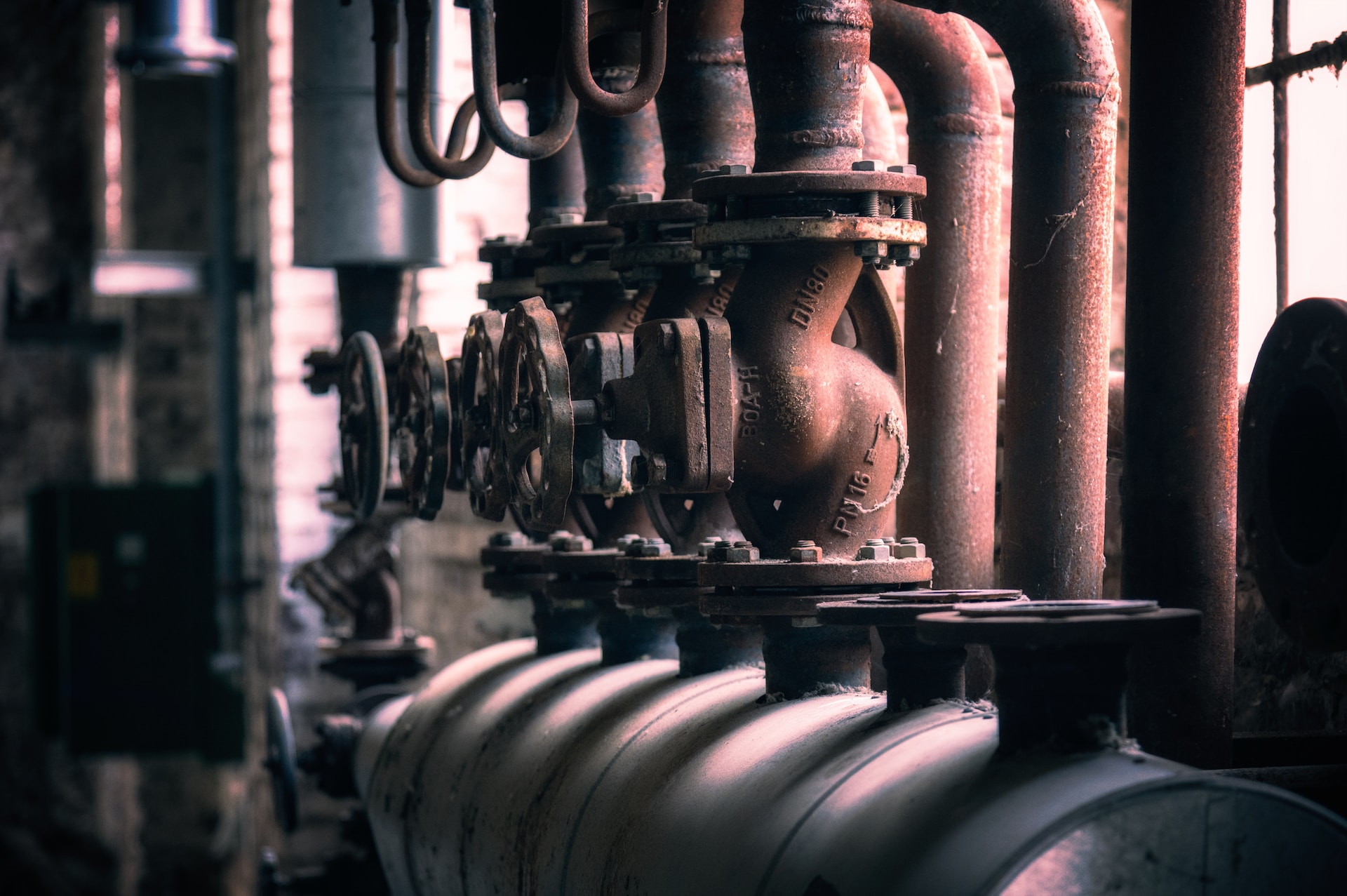

Pressure testing procedures play a crucial role in safeguarding the integrity of various industrial components and equipment, such as pipes, tanks, pressure vessels, fittings, and more. These tests are essential in new component manufacturing, routine maintenance, and quality verification processes.

Methods of Pressure Testing

Pressure testing can be conducted using two distinct methods: hydrostatic and pneumatic. Hydrostatic tests involve the use of water as a medium, while pneumatic tests use gas. There are significant differences between the two, particularly in terms of the energy released upon failure. Keep reading to delve into these variances and learn how we can ensure the safety of your staff and property in both scenarios.

When to use Pneumatic testing and Hydrostatic Testing

Hydrostatic testing, commonly used for components under high pressure, usually involves the use of water as the testing fluid, but other fluids like oil or hydraulic fluid may be used depending on the materials being tested and potential corrosion issues.

On the contrary, pneumatic testing is commonly employed for components with lower pressure requirements. Typically, air is the preferred testing medium, though nitrogen may be used in certain situations where minimal chemical reaction is preferred.

It is crucial to recognise that water and oil are considered non-compressible at typical pressure levels used during testing. This results in lower energy expenditure to achieve the necessary pressure compared to using a compressible medium. Lower energy input means lower energy output in the event of a failure.

Why is Pneumatic test more dangerous than hydrotest

Because pneumatic tests use a compressible gas, more energy is required to reach the require pressure. This energy is stored in the compressed gas and can released explosively on failure. For this reason, pneumatic testing represents a significant hazard above and beyond hydrostatic testing.

Pneumatic tests require more energy to reach the desired pressure due to the use of a compressible gas. This stored energy in the compressed gas can be explosively released in case of failure, making pneumatic testing a higher risk compared to hydrostatic testing.

Pneumatic testing poses more risks compared to hydrostatic testing due to its need for specialised training, mandatory pressure relief devices, and a higher safety rating for the enclosure.

Introduction to Hydrostatic Pressure Testing

Hydrostatic pressure testing is a common technique used to evaluate the strength and leak prevention of different systems and components, especially those meant to hold fluids or gases under pressure. This method includes applying higher internal pressure than its normal operating conditions to verify its ability to withstand such stress.

Procedure for Hydrostatic Pressure Testing

The process of hydrostatic pressure testing involves filling the object or system with water and sealing all openings and vents. Pressure is then gradually applied to reach the desired test pressure, which is maintained for a specific duration. Test Engineers closely monitor for leakage, distortion, or failure using various tools such as pressure gauges and leak detectors.

An important benefit of hydrostatic pressure testing is its ability to uncover hidden weaknesses and defects that may not be visible during normal use. By subjecting the object or system to higher pressure, any cracks, leaks, or flaws can be detected early on for timely repairs or replacements to prevent major failures. Furthermore, this testing method is non-destructive, allowing the object to be put back into operation after passing the evaluation.

Applications of Hydrostatic Pressure Testing

Hydrostatic pressure testing is crucial in a wide range of industries such as oil and gas, petrochemical, manufacturing, construction, and utilities. This testing method is commonly used to verify the strength and durability of pipelines, tanks, boilers, pressure vessels, heat exchangers, and plumbing systems. Regulatory requirements and industry standards often dictate the need for hydrostatic pressure testing in order to meet safety regulations and quality control measures.

By subjecting important equipment and systems to thorough hydrostatic pressure testing, companies can improve the reliability and efficiency of their infrastructure, reduce the chances of leaks or malfunctions, and uphold a secure working environment. This testing process is essential in safeguarding the safety and dependability of various industrial systems, instilling confidence in their performance and functionality.

Pneumatic Pressure Testing

Pneumatic pressure testing is a technique utilised to evaluate the strength and tightness of structures and parts that are built to hold pressurised gases or compressed air. This method involves exposing the object or system to internal pressure above its standard operating levels to ensure its ability to withstand such stress.

Requirements for Pressure Testing

Pressure testing is required for a variety of reasons, including:

Safety: Pressure testing ensures that a system or component can safely withstand the pressures it will be subjected to during normal operation.

Compliance: Many industries have regulations requiring pressure testing to ensure that equipment meets safety standards and prevents accidents.

Reliability: Pressure testing helps identify any leaks or weaknesses in a system, allowing for repairs to be made before a catastrophic failure occurs.

Performance: Pressure testing can be used to verify the performance of a system under various operating conditions, ensuring that it will function as intended.

Quality control: Pressure testing is often used as a quality control measure to ensure that products or components meet specified standards before they are put into service.

Troubleshooting: Pressure testing can be used to diagnose issues with a system, such as leaks or blockages, and determine the cause of the problem.

Overall, pressure testing is an essential process in various industries to ensure the safety, reliability, and performance of systems and components.