Pressure Systems (PSSR)

Introduction to Pressure System Examinations

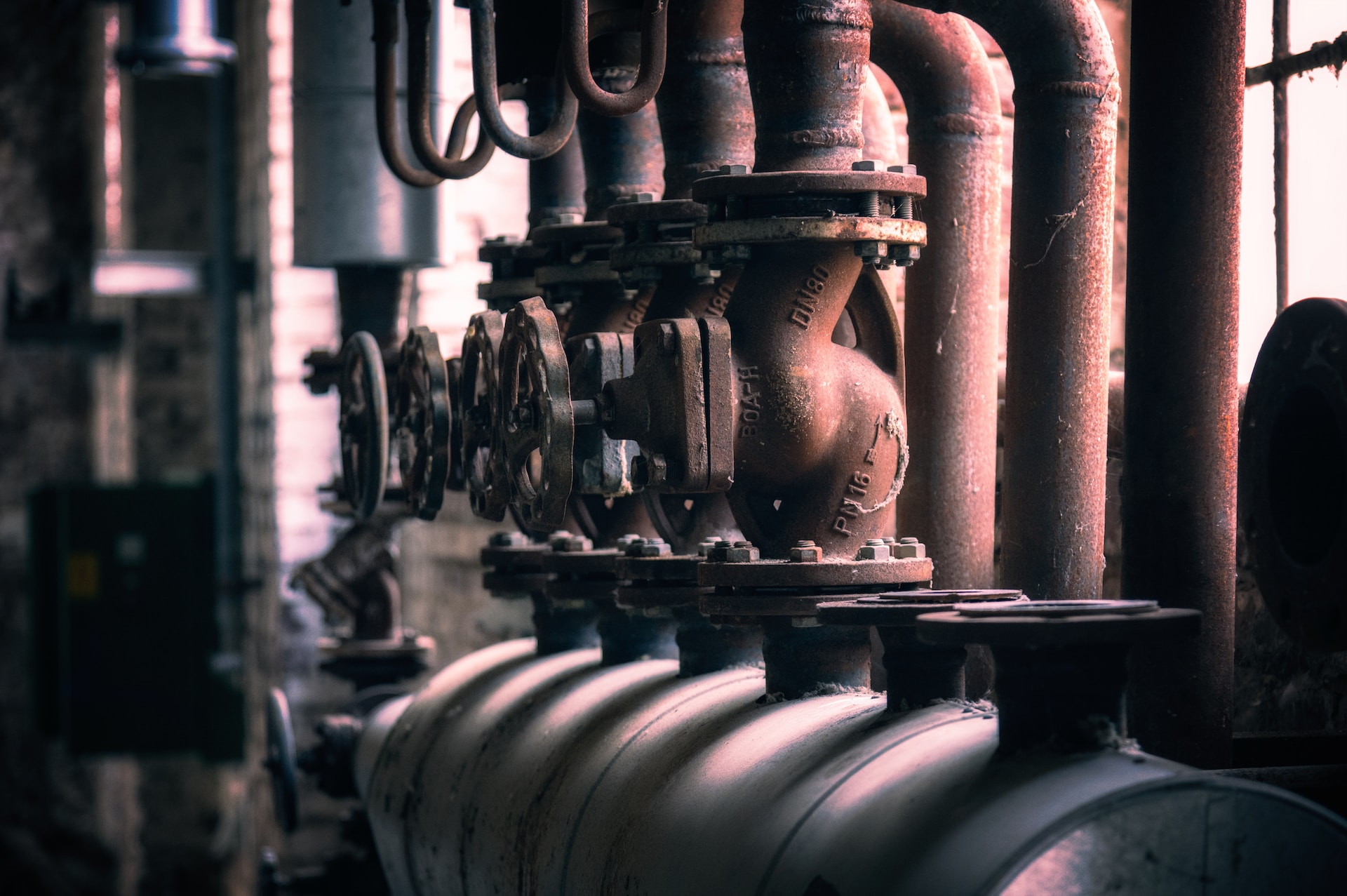

Pressure system inspections include evaluating the state and performance of equipment operating under pressure to conform to regulations and suitability for use. These assessments typically entail inspecting for leaks, corrosion, the effectiveness of safety features, and conformity with safety guidelines to mitigate hazards and safeguard individuals handling or in close proximity to pressure systems.

PSSR refers to Pressure Systems Safety Regulations. These inspections are conducted to verify that pressure systems are securely designed, installed, operated, and maintained. They are typically mandated by regulations in specific sectors to mitigate accidents and safeguard the well-being of employees and the general population. Throughout a PSSR inspection, a certified examiner will evaluate the status and condition of pressure systems, pinpoint any dangers or vulnerabilities, and suggest enhancements if necessary.

Procedure for Pressure System Examination.

PSSR (Pressure Systems Safety Regulations) inspection involves thoroughly examining pressure systems to ensure they are safe to operate. This inspection typically includes the following steps:

Examining documents: The Engineer will evaluate all pertinent documentation, including design calculations, inspection reports, and maintenance records, to verify that the pressure system was appropriately designed, installed, and maintained.

The Engineer will visually examine the pressure system for any evidence of corrosion, damage, or wear that may suggest a safety risk.

Functional testing may also be carried out by the Engineer to verify that the pressure system is functioning properly and can safely manage the expected operating conditions.

Safety device testing involves the inspector examining the functionality of safety devices, such as pressure relief valves and pressure gauges to ensure they are operating correctly and are calibrated to release pressure at the appropriate level.

Following the completion of the inspection, the inspector will create a comprehensive report listing any possible problems or safety issues and suggesting any essential repairs or upkeep.

Overall, PSSR pressure systems inspection is crucial for ensuring the safety of pressure systems and protecting against the risks associated with their operation.

Legislation

The Pressure Systems Safety Regulations 2000 (PSSR) is the main legislation in the UK that governs the safe handling of pressure systems and vessels. Employers must ensure that these systems are designed, installed, and maintained safely, with regular inspections and necessary repairs. Operators must also be trained, and competent, and detailed records of system maintenance must be kept. Non-compliance with the PSSR can lead to fines or imprisonment, so employers should be aware of and follow the regulations to protect their employees and the public.